One potential cause of damage to an XJLink2 JTAG controller is transient current spikes caused when a board is first powered on and the decoupling capacitors are charged. We’ve talked about this issue on the blog before and shown that, unfortunately, even a very brief spike in current can cause damage to the controller.

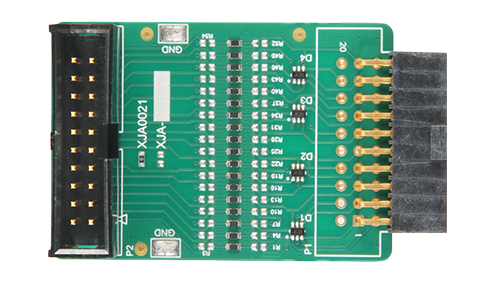

Introducing the XJTAG Termination Protection Board

The XJA-0021 Termination & Protection Board helps mitigate this problem. This board can be connected between an XJLink2 and the UUT, adding a 47 ohm series resistor on each I/O pin. These resistors act to limit the current that can flow through the pin, preventing damage to the controller.

The resistors also provide series termination which can improve signal integrity in some cases, allowing the JTAG chains to run faster and more reliably when termination has not been designed into the units under test.

The I/O pins on the Termination & Protection board each have additional pads. Populating resistors onto these pads allows signals to be divided before reaching the controller, meaning that a greater range of voltages can be read by the ADCs in the unit.

The Termination & Protection Board functionality has not been embedded in the XJLink2 because it can combine with capacitors on nets on a UUT to introduce a time delay – we have seen this issue on some reset lines.

We believe that this board will offer improvements to reliability and reduction in ongoing costs, not only due to reducing the risk of incurring repair costs for damaged controllers, but also by helping to ensure that testing on the production line doesn’t have to be halted while a controller is replaced.

Leave A Comment